We collect basic website visitor information on this website and store it in cookies. We also utilize Google Analytics to track page view information to assist us in improving our website.

Brake press forming is a widely used metalworking process that involves the use of a brake press machine to shape sheet metal into a desired form. This technique is commonly employed in the manufacturing industry to create parts for various applications such as automotive, aerospace, and construction. For LMP, the importance lies with the customer’s requirements. Once an AutoCAD file is provided, we are able to process the drawing and form the part according to the customer’s print.

There are two main types of brake press machines: hydraulic and mechanical. Hydraulic machines utilize hydraulic cylinders to apply pressure on the sheet metal, while mechanical brake press machines utilize a clamping bar and mechanical levers for pressure application. Both types of machines are capable of producing accurate and precise results, however, hydraulic brake press machines tend to be more powerful and can handle thicker sheet metal.

Brake press forming can be utilized to produce a wide array of products, including automotive body panels, aircraft wings, and construction components such as steel beams, channels and braces. The process begins by placing the sheet metal on the bed of the brake press machine and securing it in place. The operator then selects the appropriate die tooling and sets the machine's parameters, including the pressure amount and bend angle.

Once the machine is set up and the sheet metal is secured, the operator activates the machine and the press applies pressure on the sheet metal, bending it into the desired shape. The operator may need to make multiple passes to achieve the desired shape or form multiple bends in the sheet metal. In addition, brake press forming can be performed with a variety of materials including mild steel, aluminum, and stainless steel.

At LMP, we understand that brake press forming offers numerous advantages compared to other metalworking techniques. It is highly accurate and can produce complex shapes with precise dimensions. It is also a rapid process, with some machines capable of producing hundreds of parts per hour. Coupled with our ability to utilize our four fibre lasers, Oxy and plasma department and secondary welding location, we are able to offer a one-stop-shop service for our customers.

In conclusion, brake press forming is an essential process in the manufacturing industry, enabling the production of a wide range of products with high accuracy and efficiency.

We would like to thank you for reading our blog post! We are thrilled to be a trusted customer and supplier for those in Ontario!

Stay tuned for future blogs!

Sincerely,

The Laser Metal Profiles Team

Thank you for reading our blog post! Don't forget to leave a Google Review and follow us on our social media accounts!

Instagram: @LaserMetalProfiles

LinkedIn: Laser Metal Profiles Limited

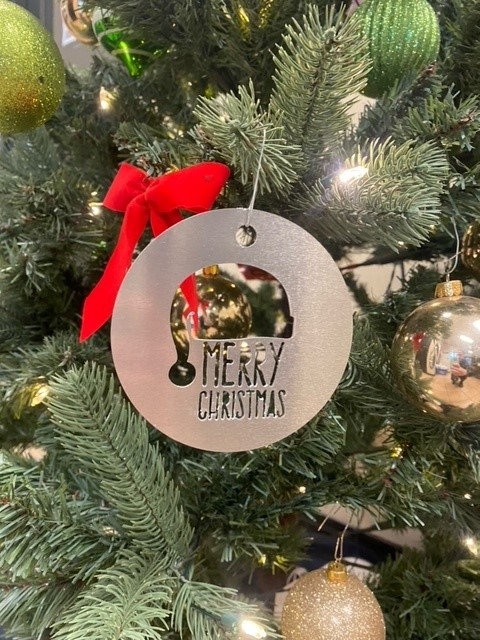

The Christmas spirit has entered the building!

We are delighted to include our own personal touch in the office this season. This year, not only are decorations up and Christmas cheer is high, but we also have had the opportunity to test out our fibre laser technology. We have done this by cutting custom ornaments and decorations for a more personalized LMP Christmas season!

Our fibre lasers have enabled us to create made-to-order designs for our facility and customers. As seen in the picture below, we have created wall art to bring some personal touches to the office. In doing so, we are showcasing a wide variety of what we can offer our customers. With the precision of 0.010 of an inch on our laser cutting machines, this allows for us to supply intricate details and designs. In other words, there isn't a job too big or too small for us!

In keeping with the Christmas theme, we are grateful for the family-oriented culture that's been established at LMP. In sharing like-minded morals and values, as a company, we understand that each of us have a role to play when it comes to helping the business be sucessful.

If custom designs sparks your interest, give us a call! Additional photos of our work can be found on our website by clicking the "gallery" tab.

We would like to thank you for reading our blog post! We are thrilled to be a trusted customer and supplier for those in Ontario!

Stay tuned for future blogs!

Sincerely,

The Laser Metal Profiles Team

Thank you for reading our blog post! Don't forget to leave a Google Review and follow us on our social media accounts!

Instagram: @LaserMetalProfiles

LinkedIn: Laser Metal Profiles Limited

We are delighted to announce that on October 2nd, Laser Metal Profiles celebrated our 20th anniversary! Being that this is a Canadian family-run business with three generations working within the facility, from the beginning, an emphasis on providing sound values and equitability for all employees is of the utmost highest priority for the owner. Starting when the president and his father were personally delivering customer orders on a pick-up truck, to now having multiple transport trucks filled daily, the company has developed with the help of its employees, customers and suppliers.

As the LMP family has grown throughout the years, we are extremely grateful for all involved in helping us reach this milestone. Most importantly, we owe it to the employees. The employees have established a family-oriented culture that aims to instill hard work and team spirit every day. Anne M. Mulcahy, a reputable entrepreneur in the marketing and sales industry, focuses on key concepts that LMP strives to achieve, “employees are a company’s greatest asset – they are your competitive advantage…you want to make them feel like they are a part of the company’s mission”, With an emphasis on viewing each other as equals, we understand that each person plays an integral role in the day-to-day business operations. As such, we ensure we give back by way of monetary bonuses and incentives, company-branded items, monthly food trucks, pizza lunches and many more.

For the relationships we have built with our suppliers and customers, we thank them for the quick service, quality materials and friendly individuals to work with. Rather than viewing suppliers and customers as such, we value our established partnerships with them. Whether that be supporting each other through a recession, a pandemic or the daily challenges experienced in the business world, we are pleased to work with top-class individuals and companies.

We would like to thank you for reading our blog post and are thrilled to be a trusted customer and manufacturer for many in Ontario!

We hope you enjoyed getting to know some of our team, stay tuned for future blogs!

Sincerely,

The Laser Metal Profiles Team

Thank you for reading our blog post! Don't forget to leave a Google Review and follow us on our social media accounts!

Instagram: @LaserMetalProfiles

LinkedIn: Laser Metal Profiles Limited

Over the past few weeks, we have been in the midst of setting up our new ten thousand watt Trumpf laser. As a collective, from the dedicated workers running the machines to the sales and programming departments within the company, everybody has been looking forward to the moment when this machine begins operation.

One of the biggest assets of this new machine is the capabilities. For reference, this machine can cut at ten thousand watts, whereas, our previous machine cut at four thousand watts. With this large increase in cutting speed, we can enhance and continue with our commitment to serving our customers with the best manufacturing service in Southern Ontario. Additionally, this broadens the proficiency of the company as a whole. Ensuring that our fabrication is done accurately and on-time is of the utmost importance for LMP. Moreover, as we are moving on from a machine with a 60” x 120” cutting area to an area that is 72” x 144”, LMP can supply larger parts and more parts per sheet as the cutting area has increased. With four Fiber machines now operating at our location, we are devoted to ensuring that LMP stays up to date with the leading technology to best serve our customers.

If you have any questions, feel free to reach out to us via our Contact Us page.

Thank you for reading our blog post! Don't forget to leave a Google Review and follow us on our social media accounts!

Instagram: @LaserMetalProfiles

LinkedIn: Laser Metal Profiles Limited

Laser cutting, the foundational aspect of our business processes at Laser Metal Profiles, is a thermal operation that uses a laser beam to pierce and slit raw material in an isolated area. Essentially, the laser powered beam is concentrated on a single point that has a diameter ranging from 0.08 mm – 1 mm depending on the thickness and type of material. At LMP, as seen on our products page, we exclusively cut steel. With this, the laser cutting process can be broken down into an eight step process.

1. Optics: Focusing the beam

The laser cutting equipment that operators use at LMP include two important components: the lens and mirror optics. Without these, the machine will cut inaccurately and inefficiently. The focus is achieved through the use of multi-lens optics that measure the focal length and the diameter of the space in-between. Moreover, the mirrors act as a guide for the lens so that it can verify the horizontal coordinates on the grid are correctly located to ensure the cut is done correctly according to the documents provided by the customer.

2. The Laser Beam

The mechanism that is responsible for cutting through the material is known as the laser beam. This is exactly how it sounds; a beam is directed to a localized area that heats up the material to the point where it either evaporates or melts. Once this happens the process of cutting has occurred. Interestingly, the process includes no contact which ensures that the parts that are being cut incur no damage. Considering the beam is guided based upon a program created by our CAD department, LMP ensures accuracy and proficiency.

3. Cutting Gas

At LMP, our machines use oxygen, nitrogen, and compressed air as the cutting gas. Oxygen or argon gasses are also used for laser cutting machines but the latest technology of these machines use oxygen and nitrogen as the preferred gas types. Another benefit that these gasses have is that they have virtually no reaction to the melted metal which in turn, prevents residue on the customers parts or in the environment. Additionally, the reduction of burrs are often observed in aluminum, stainless steel or mild steel material when being cut with the use of nitrogen gas.

4. Drag lines

When laser cutting, there are “drag lines” on the surface of the part. It is known to be a good cut when the lines are thinly and consistently present along the parallel line of the part. Essentially, this pattern is parallel to the cutting head and beam of the laser. An example is provided in the photo below. This can be perfected by ensuring the machine set-up prior to cutting.

5. Melt

Whenever raw material is cut, as mentioned above, the beam is strong enough to melt the material at the localized point. In other words, the beam emits a certain amount of energy where at its threshold,it will burn right through and oxidize the steel being cut.

6. The Cutting Point

This part of the process is the most critical for ensuring the parts are cut cleanly and without a great amount of residue. On the laser cutting table, there are coordinates for the cutting head to calibrate to. This streamlines the operations as it allows for the cutting head to get the most precise cut and location.

7. The Nozzle

The brass nozzle is at the bottom of the cutting head, the closest point to the material on the machine's table. As such, this is an important part of the cutting process because this is where the gas used for cutting and the beam of the laser intersect. Moreover, there are different types and sizes of nozzles. In short, this can include specific shapes that are optimal for cutting speed, edge quality or gas optimization.

8. The Cutting Direction

When the cutting head is moved around the X and Y axis during the programmed cutting schedule, a kerf is formed. An important caveat with the counting direction is the laser light that guides the cutting head. If the light is parallel to the cutting direction, a smooth edge will result. If the light is perpendicular to the cutting direction, it will create a burr on the material. The cutting quality is contingent on this aspect. Evidently, the cutting direction must be properly set-up to ensure the most accurate cut possible.

As described throughout this article, the intricacies of each process in the laser cutting process is equally important so that the machine can function properly. When they all come together, the laser cutting quality and efficiency reaches optimal levels

Thank you for reading our blog post! Don't forget to leave a Google Review and follow us on our social media accounts!

Instagram: @LaserMetalProfiles

LinkedIn: Laser Metal Profiles Limited

============================================================

References

Laser cutting as a contact-free slitting process. (2022). TRUMPF. Retrieved May, 2022, from https://www.trumpf.com/en_CA/solutions/applications/laser-cutting/